*Click on the Experience the production process button below to view the entire production process in a new window.

- 01. Stock

Preparation -

- 1Pulper

- 2Refiner

- 3Blend

-

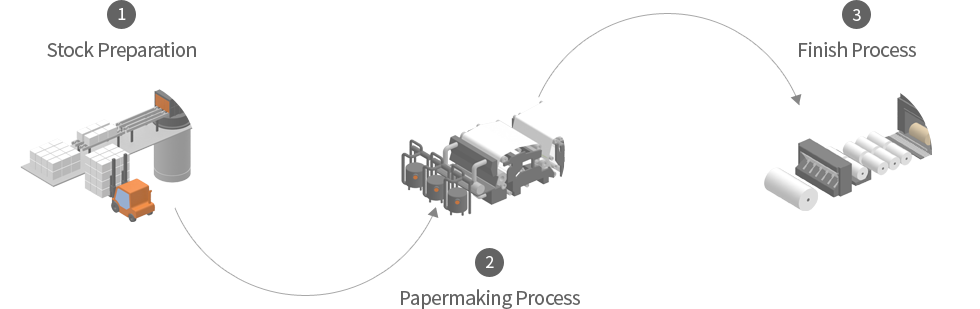

Stock preparation, as a process immediately before sending the paper stock to the papermaking machine, determines the fundamental quality characteristics of the paper. Pulp, which is the main ingredient of the paper, undergoes dissociation and beating process, the blending process of mixing various chemicals including filler, Jeongseon and Dementia processes in the cleaner, scree and others then is sent to the head box of the paper making machine.

- 02. Papermaking

Process -

- 1Head Box

- 2Wire

- 3Press

- 4Pre Dryer

- 5Size Press

- 6After Dryer

- 7Machine Calendar

-

Papermaking process, as a process of dehydrating and drying the paper stock to make paper, is comprised of creating stratum, compression and dehydration, drying, surface treatment and others. The raw material ejected from the head box is formed into web on the wire part, undergoes compression and dehydration process in the press part, residual moisture is evaporated in the dryer part, the thickness of the paper is controlled in the calendar then made into a product.

- 03. Finish Process

-

- 1Rewinder

- 2Roll Package

- 3Stock & Release

-

Finish process, as a process of fabricating into roll or sheet and packaging the papers that have completed the paper making or coating process in accordance with the requirement of the consumer, involves supplying the paper that has undergone such processes to the consumers.